Comparing 3d Printed Freight Cars Against Kits of the Past

March 18, 2018

Our Hart gondolas are special because they represent models that haven’t been done accurately in HO.

Our Hart gondolas are special because they represent models that haven’t been done accurately in HO. When I talk about the Hart gondolas, like to highlight how the models represent freight cars that haven’t been done accurately in the past. There’s no resin kits, no brass cars. However, we did have two cars in the past: the craftsman kits from Silver Streak in the 1960’s, and Train Miniature’s plastic shake-the-box kit from the 1970’s. Both are good for their time, but we can do a lot better in the 2010’s.

How much better? Let’s compare the Dry Creek Models Hart gondola against the Silver Streak and Train Miniature kits. I picked up both at a train show recently.

[ Silver Streak ]

Let’s first look at the Silver Streak kit. For the time, this is a neat kit. It has the underframe trusses from the real car, side-mounted brake cylinder, and matches the SP cars with eight posts on each side.

The kit also lacks the car sill at floor level on the real cars, instead showing siding going all the way down to the bottom edge of the car.

Just like the modernized SP cars, the Silver Streak Car has grab irons on each end supported by a short vertical piece of wood. It’s also missing all the door hardware; the real cars had castings at the bottom of each post, but that’s a pretty tiny detail to include. The modeler who built this kit didn’t quite get the partitions at the correct location - they should line up with the outer post.

The model’s a little coarse with 6x6 strip wood serving for the top rail and for the posts, but it’s a fair tradeoff for intermediate modelers building their first car. It’s nice to see the board detail on the inside faces of each side. It’s also a bit oversize, with the sides measuring almost five feet high compared to three on the real car.

[ Train Miniature ]

Here’s the Train Miniature car. Again, it looks like it got inspired by the Southern Pacific cars that would have been seen in the 1930’s and 1940’s… or they just copied the Silver Streak car. The car has the correct eight spaces between posts. The grab irons don’t match the real car. More importantly, the trusses are pushed out to be even with the sides - definitely not how the real car was built. Like the Silver Streak car, Train-Miniature left out the car floor visible on the sides. Again, the car sides are taller than

[ Dry Creek Models ]

And finally, here’s the Dry Creek model. I pulled out one of my “original” cars just to highlight the detail. 3d printing gives us a lot of advantages, including the ability to throw in all that detail for the door hinges , the door latch mechanisms on the posts, and the various bolts all over the model. The truss is lighter than the Silver Streak car, we can see the car side frame and floor.

[ Top down ]

Here’s all three from the top: Silver Streak on the left, the Train Miniature, then Dry Creek’s 3d printed model. The Silver Streak car did correctly model the sloping hopper. It’s not perfect; this kit shows the hopper as incorrectly extending up along the bulkheads on each end. But I’m pleased to see they included the supports that ran through the hopper, even if they’re incorrect. There’s no detail on the doors, but then that’s a pretty tiny detail.

The Train Miniature kit’s hopper is hidden by the load, but that brake cylinder and brake gear in each end is completely wrong for the car, and misses the fact that those partitions were meant to be removable so the car could be used as a typical gondola.

And finally, for the Dry Creek models version. We see the braces running through the hopper (with the notch to hold the 4x10 that supports the doors when closed. We see the end bulkheads definitely look removable. On the far end of the car, you also might see the hinged apron that allowed running a plow through all the cars - a detail that wouldn’t be needed on either of the other modernized cars, but does highlight how 3d printing lets us throw all that sort of detail on the car.

[ Bottom ]

Finally, here’s the underside of each car - Silver Streak on the left, Dry Creek in the middle, Train-Miniature on the right. This photo highlights how the other two cars are a bit oversized compared with the actual cars, and the needs of manufacturing made details like the trusses much more clunky than on our 3d printed model. Both Silver Streak and Train Miniature made some parts oversized (like the trusses) and also placed the trusses differently to make the car easier to manufacture. Both also had to lose some of the interesting detail: braces for the trusses, side sills, etc. in order to make an economical and easy to build kit.

All in all, the Silver Streak and Train Miniature kits are fine for both their time and for what they’re intended for. They had to design parts to be manufacturable (Train-Miniature moving the trusses out), needed oversized parts for easier assembly, dropped details to keep part counts low or permit injection molding, and did the best they could from photos.

The Dry Creek model, instead, gets to benefit from being 30 years in the future. I had access to the SP blueprints which the earlier manufacturers may not have had. 3d printing meant I could make parts closer to scale, and could easily add details that would have been impossible with injection molding. 3d printing also allowed me to refine the models, and quickly make variants: doors up vs. doors down, or the modernized cars without the side dump doors. If I found some railroad back east had a similar car but with a minor tweak, I could make that too. If I was injection molding, I would have had one shot at making the molds, and would have focused on making only the kit that would be most popular.

Hart Gons in Use on the Pacific Electric

December 03, 2016

I'd mentioned in the past that the Pacific Electric had Hart W-50-3 gondolas running through the 1940's. This photo, from the November 1944 Pacific Electric employee newsletter (available from the Metropolitan Transportation Administration's archive website) shows a Hart gondola being used in ballast service in 1944. (Click through to the full newsletter; the article has several pictures on track improvements along the mostly-freight West Basin line.

The photo doesn't show the car dumping ballast; instead the caption reads "gravel train backs up and spreads dumped ballast". The crews used the Hart cars to dump a foot of gravel between the track. However, they still had to push the pile around to get it between the tracks. The temporary wooden boards at rail level (with undetermined bracing) looks awfully flimsy, but it must have worked!

The photo doesn't show the car dumping ballast; instead the caption reads "gravel train backs up and spreads dumped ballast". The crews used the Hart cars to dump a foot of gravel between the track. However, they still had to push the pile around to get it between the tracks. The temporary wooden boards at rail level (with undetermined bracing) looks awfully flimsy, but it must have worked!

Brake Gear and Hart Gondolas

March 17, 2016

Brakes and Hart Gondolas

When I did the initial research for the Hart convertible gondolas, I was able to find great drawings of the car bodies, but little on the brake equipment. The California State Railroad Museum has a few drawings of the W-50-3 gondola, all with beautiful detail. There was no information either about the routing of the brake rodding, or details about pipelines and fittings.

The current Hart gondola kit instructions suggest a possible “simplified” brake rigging for modelers who want to get this detail perfect. On my own cars, I added this “simplified” brake gear on about half the cars, but did minimal detail on the others. My layout, after all, is an operating layout, and having cars that work smoothly and don’t hang up matters more to me than having contest models.

I know many others who want their cars to be perfect, right down to the brake gear. Luckily, I found another source for information about these cars. The SP’s W-50-3 happens to be a “Common Standard” design, shared between the different Harriman-owned railroads through the ‘teens, so the Union Pacific or Pacific Electric also had the cars.

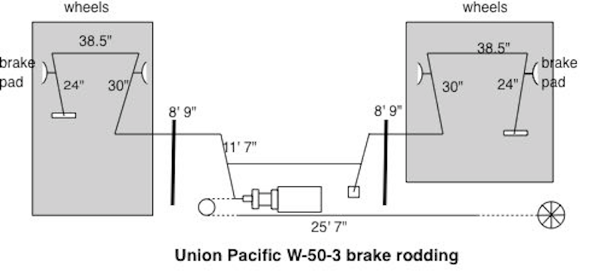

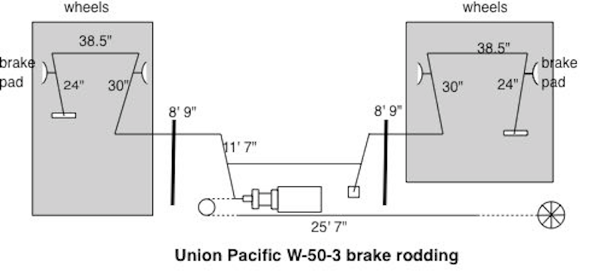

California State Railroad Museum’s collection of Union Pacific blueprints gave the missing link. UP’s “Air Brake Folio (dated March 5, 1919, book 430, drawing 5242-30) had schematic drawings of many cars. That drawing of the W-50-3 brake gear highlights exactly how the rodding was placed.

There’s some key details worth noting if you want to install prototypical brake rodding:

1) Note that the brake cylinder end attaches to a chain that goes around a pulley before stretching to the brake wheel. On all the Southern Pacific cars I’ve seen, no such pulley exists; the brake wheel pulls a chain directly connected to the brake cylinder.

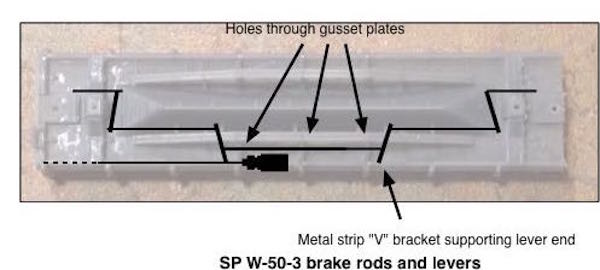

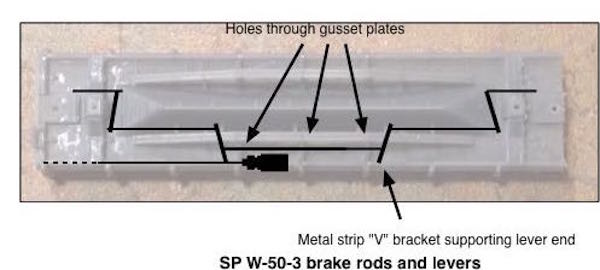

2) The 11’ 7” rod behind the brake cylinder is interesting; on the real cars, it had to pass through holes in two gussets attaching the Hart truss to the car floor.

3) The pivot point behind the brake cylinder does appear on the real cars as a pair of steel straps in a V design holding the pivot end of the brake rod. This pivot support isn’t easily seen in all photos, but the builder’s photo of Pacific Electric 6000 in Tony Thompson’s “Southern Pacific Freight Cars” book shows the support faintly.

If you'd like to put full brake gear on your SP W-50-3 Hart convertible gondola, here's how the rodding would fit on the car body.

The UP’s “Air Brake Folio (dated March 5, 1919, book 430, drawing 5242-30) is available at the California State Railroad Museum; the image of the blueprint is on microfilm.

When I did the initial research for the Hart convertible gondolas, I was able to find great drawings of the car bodies, but little on the brake equipment. The California State Railroad Museum has a few drawings of the W-50-3 gondola, all with beautiful detail. There was no information either about the routing of the brake rodding, or details about pipelines and fittings.

The current Hart gondola kit instructions suggest a possible “simplified” brake rigging for modelers who want to get this detail perfect. On my own cars, I added this “simplified” brake gear on about half the cars, but did minimal detail on the others. My layout, after all, is an operating layout, and having cars that work smoothly and don’t hang up matters more to me than having contest models.

I know many others who want their cars to be perfect, right down to the brake gear. Luckily, I found another source for information about these cars. The SP’s W-50-3 happens to be a “Common Standard” design, shared between the different Harriman-owned railroads through the ‘teens, so the Union Pacific or Pacific Electric also had the cars.

California State Railroad Museum’s collection of Union Pacific blueprints gave the missing link. UP’s “Air Brake Folio (dated March 5, 1919, book 430, drawing 5242-30) had schematic drawings of many cars. That drawing of the W-50-3 brake gear highlights exactly how the rodding was placed.

There’s some key details worth noting if you want to install prototypical brake rodding:

1) Note that the brake cylinder end attaches to a chain that goes around a pulley before stretching to the brake wheel. On all the Southern Pacific cars I’ve seen, no such pulley exists; the brake wheel pulls a chain directly connected to the brake cylinder.

2) The 11’ 7” rod behind the brake cylinder is interesting; on the real cars, it had to pass through holes in two gussets attaching the Hart truss to the car floor.

3) The pivot point behind the brake cylinder does appear on the real cars as a pair of steel straps in a V design holding the pivot end of the brake rod. This pivot support isn’t easily seen in all photos, but the builder’s photo of Pacific Electric 6000 in Tony Thompson’s “Southern Pacific Freight Cars” book shows the support faintly.

If you'd like to put full brake gear on your SP W-50-3 Hart convertible gondola, here's how the rodding would fit on the car body.

The UP’s “Air Brake Folio (dated March 5, 1919, book 430, drawing 5242-30) is available at the California State Railroad Museum; the image of the blueprint is on microfilm.

Hart Gondolas on the Pacific Electric

December 07, 2015

The Pacific Electric’s Hart convertible gondolas were exact matches to the SP W-50-3 gondolas as they were built by the Southern Pacific and Union Pacific. These cars were initially numbered 6400-6449, but quickly changed to 6200-6249 by 1914. The equipment diagram for the cars (shown in Ira Swett’s Cars of the Pacific Electric vol. 3, 2nd edition) show a car with identical dimensions to the SP’s cars. Unlike the SP cars, the PE cars kept their side dump doors. A photo of car #6241 in Swett’s book shows the PE car at the end of its life: side dump doors still opening, latches on alternate doors, and the like. A separate photo in Thompson’s “Southern Pacific Freight Cars” shows a swaybacked string of Hart gondolas still in use in the late 1940’s; another photo (from the MTA archives) shows a Hart gondola in West Hollywood’s Sherman Shop complex, ready with a load of ballast.

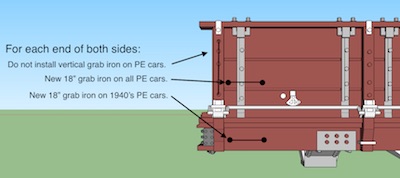

The surviving photos do suggest two differences. The original cars SP had vertical handholds on each corner of the car. PE’s cars, as seen in a 1912 photo, instead show a horizontal grab iron on the sides about 14 inches above the floor of the car. By 1950, the PE added a second handhold on the side sill.

The other significant difference involves the wheels. As seen in the builder's photo in SP Freight Cars, the Pacific Electric gondolas were built with arch bar trucks. Later photos shows the cars with the same arch bars. These trucks differed from the arch bar trucks we normally see on HO models. Rather than having a bottom bar that sloped up from the bolster to the journal boxes, the bottom bar of these trucks was parallel to the rail.

If you’re a Pacific Electric modeler and want a string of Hart gondolas for your maintenance of way crew, the “SP car as built” model is nearly identical to the PE’s actual car. Omit the vertical handholds, and drill holes for the four new grab irons on each side. Note that our SP W-50-3 gondola kit contains some PE lettering on its decal sheet, but doesn't include the white Pacific Electric logo seen on 1940's freight cars. We don't know a good HO wheel set for those arch bar trucks, but suspect any of the commercial arch bar trucks would still look good under the car.

For more information:

Ed Workman, Common Standard Freight Cars: Pt. 1. In Union Pacific Historical Society Streamliner magazine, vol 11(4), 1997.

Ira Swett, “Cars of the Pacific Electric”, volume 3. Interurban Press, 1975. Diagram of the Pacific Electric 6200 series gondolas, and photo of car 6241 in the 1940’s.

Tony Thompson, “Southern Pacific Freight Cars Volume 1”. Photo of PE car in 1912 and another of a string of swaybacked gondolas in the 1940’s.

How About Those Notches?

October 15, 2015

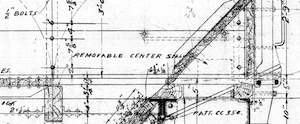

Some small print on the plans explains it: "5" x 9" removable center sill Dwg. No C-1852". The doors covering the hopper were wood, reinforced with metal strips, and weren't strong enough to support a full load on their own. A thirty foot 5" x 9" beam (or maybe two beams, one stretching to each end of the car) sat underneath, on top of the cross-beams, acted as support for the doors. One of the end drawings also helpfully notes that the sill would be stored behind the doors when the hopper doors were opened.

Engineering drawing excerpt from Southern Pacific Common Standard plan C-1652 "Work Car Class W-50-3", in the collection of the California State Railroad Museum in Sacramento. If you're obsessed about these cars as much as I am, call them up and ask about getting a copy of the full plan for yourself.